Anode Material for Battery Manufacturers

Targray supplies a complete portfolio of anode materials for lithium-ion battery manufacturing. Our high-performance anode powder portfolio includes natural and artificial graphite, activated carbon, carbon black, conductive additives, LTO (lithium titanate), surface-functionalized Silicon, and high-performance powdered graphene.

The vast majority of lithium-ion batteries use graphite powder as an anode material. Graphite materials are either synthetically-produced (artificial graphite) or mined from the ground (natural graphite), then heavily processed before being baked onto a copper foil to serve as anodes. Graphite anodes meet the voltage requirements of most common Li-ion cathodes, are relatively affordable, extremely light, porous and durable.

Anode Material Requirements

In order to be suitable for lithium-ion battery manufacturing, anode materials should meet the following requirements:

- Excellent porosity and conductivity.

- Good durability and light weight.

- Low Cost.

- Voltage match with preferred cathode.

Active Anode Materials

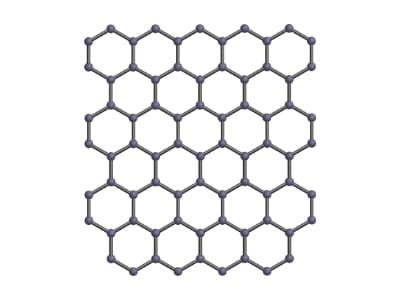

The anode (or negative electrode) in Lithium-ion battery is typically made up of Graphite, coated on Copper Foil. Graphite is a crystalline solid with a black/grey color and a metallic sheen. Due to its electronic structure, it is highly conductive and can reach 25,000 S/cm2 in the plane of a single-crystal.

Graphite is commonly used as the active material in negative electrodes mainly because it can reversibly place Lithium-ions between its many layers. This reversible electrochemical capability is maintained over several of thousands of cycles in batteries with optimized electrodes. However, one requirement for this application is that the Graphite surface must be compatible with Lithium-ion battery chemistry (salts, solvents and binders).

Anode Binders

Targray supplies a portfolio of Binders materials: Styrene Butadiene Copolymer (SBR) and Polyvinylidene Fluoride (PVDF), used in the cathode and anode electrode slurry making process for Lithium-ion batteries. Binders such as SBR and PVDF, are used in Lithium-ion batteries to hold the active material particles together and in contact with the current collectors i.e. the Aluminum Foil (Al foil) or the Copper Foil (Cu foil).

Foils

Targray offers a range of Copper foils depending on the application of the Li-ion battery. A rolled foil (RA-type), made from wrought Cu is generally used for high-energy, high-power applications such as drivetrain and power tools.

An Electro-Deposited (ED) foil is used in high-energy, low-power applications such as Li-ion batteries for cell phones, laptops and consumer electronics. Nickel foil is electroconductive, and is used when there are requirements for its high anti- corrosion properties and ultra-thin profile. It can be produced wider and thinner than the more commonly used rolled Copper foil.

Working collaboratively with our supply partners and organizations including the Electrochemical Society and NAATBatt, we help lithium-ion battery manufacturers worldwide commercialize ambitious new technologies for the energy storage market.