Process of Manufacturing Pouch Cell

Step 1: Electrode Sheet Preparation

- Use furnace to sinter raw cathode active material and anode active material.

- Use milling machine to mill materials into smaller-sized particles.

- Mix active, conductive and binder material into paste under vacuum using mixer.

- Use a coater to coat paste onto current collector to create electrode.

- Use a heater to dry the newly-created electrodes.

- Use the rolling press (calendar) to roll the electrode to required thickness.

Step 2: Li-ion Cell Assembly

Using Stacking Method

- Use Electrode Mould Cutting Machine to cut electrode out with lead.

- Use Stacking Machine to stack layers in the following order: Anode > Separator > Cathode > Separator

- Weld current collector and tab together using Ultrasonic Welding Machine.

- Use a Short-Circuit Detector to test the cell’s integrity.

- Dry the cell using a vacuum oven.

Using Winding Method

- Use Slitting Machine to slice electrode sheet into strips.

- Use Winding Machine to wind strips in the following order: Anode > Separator > Cathode > Separator

- Weld current collector and tab together using Ultrasonic Welding Machine.

- Use a Short-Circuit Detector to test the cell’s integrity.

- Dry the cell using a vacuum oven.

Step 3: Formation & Sealing of Battery Case

- Use Cup Forming Machine to punch cup and gas receiver on Aluminum lamination sheet and place cell into cup.

- After doubling up, seal the appropriate sides using a Top & Side Heat Sealing machine.

- Use Electrolyte Filling System to fill electrolyte into vacuum/globe box.

- Seal longer side (where gas receiver is located) using a Vacuum Sealing Machine.

- Use Battery Analyzer to charge & discharge the cell. This enables battery formation and sends excess gas to gas receiver.

- Cut off gas receiver and use Vacuum Sealing Machine to finalize sealing on cutting edge under vacuum/glove box.

Step 4: Battery Testing

- Test the newly-created battery’s performance using a Battery Analyzer.

- Use an Impedance Tester to measure the battery’s internal resistance.

Working alongside organizations including Electrochemical Society and NAATBatt, we’re focused on helping battery manufacturers commercialize ambitious new energy storage technologies.

Related Battery Materials

Pouch Cell Manufacturing

Lithium-ion Pouch Cell Manufacturing can be broken down into 4 stages: Electrode preparation, Cell assembly, Case formation & sealing, and battery testing.

Coin Cell Manufacturing

Lithium-ion coin cell manufacturing process using li-ion battery R&D equipment. Fabrication involves 3 simple steps.

Electrolyte Solutions

High performance battery electrolyte solutions. Produced with LiPF6 salt and a high phosphorous content flame retardant, DMMP.

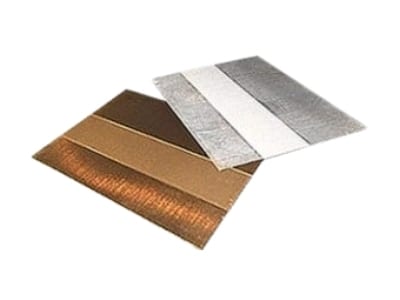

Copper Foil

An anode foil portfolio of copper current collectors including Electrodeposited (ED), rolled annealed (RA) and roll-clad Cu foils.

Nickel Foil

Annealed, ED nickel foil materials. Engineered to meet the performance demands of lithium ion battery manufacturers.

Graphite Anode Materials

Battery grade graphite powders for li ion cells manufacturers. Products include natural, artificial and composite graphite.

Battery Packaging

A large selection of battery packaging materials. Products include battery tabs, aluminum laminate film, and prismatic cans, cases & lids.