Prismatic Battery Cans for Lithium-ion Cell Manufacturers

Targray supplies seamless, deep-drawn, aluminum alloy prismatic battery cans, cases and lids for the Lithium-ion car battery market. The products are used by li-ion manufacturers for superior cell protection and added safety. Our prismatic cans are part of the next generation of cell packaging for Electric and Hybrid Powertrain Vehicle (EV & HPEV) batteries. They are safe, reliable enclosures with comparative costs and customizable dimensions. OEMs can specify their desired wall thickness, electrode location, ventilation hole(s) placement and more.

Targray Battery Casing Solutions

- Solid Aluminum construction – Available in a range of Aluminum alloys and tempers

- Customized specifications

- Puncture resistance

- Additional Safety

- High Quality

- Low Cost

The Role of Prismatic Battery Cans in Battery Production

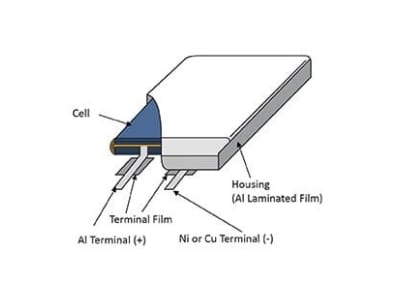

To ensure maximum usage of space, Lithium-ion prismatic cell manufacturers prefer to layer their cells, which requires that they be in highly resilient packaging. Using deep-drawn, seamless aluminum materials ensures that the prismatic battery cans are leak resistant and able to withstand external shocks. Once the prismatic cell is assembled, the lid is laser welded to the can, a high precision welding process that allows for some expansion and contraction of the cell as it heats up and cools down during use, while ensuring there are no problems with electrolyte leakage.

All of our cases, cans and lids are aligned with these requirements and needs.

Working closely with our supply partners and organizations including the Electrochemical Society and NAATBatt International, we help lithium-ion battery manufacturers worldwide commercialize ambitious new technologies for the energy storage market.

Related Battery Materials

Battery Tab Materials

Our battery tab includes aluminum (Al) tabs for positive electrodes, and copper (Cu) tabs for negative electrodes.