Biodiesel for the Underground Mining Sector

Underground mining has been identified as a key development sector for the biodiesel industry, due to the reliance of underground mine operators on diesel fuel to power underground mining equipment and machinery, and due to concerns surrounding diesel particulate emissions, which has a direct effect on worker respiratory health. The Mining Safety and Health Administration (MSHA) is directly responsible for insuring the health of underground mining workers in the United States. This involves controlling their exposure to diesel particulate matter resulting from the combustion of diesel fuel in underground mining equipment used to mine metals and non-metals in underground mines. To control exposure to acceptable levels, MSHA sets forth health standards surrounding diesel particulate matter emissions in underground mining operations. One such standard is to limit underground mine worker exposure to 160 micrograms of total carbon (TC) per cubic meter of air (160TC μg/m3)for every 8-hour shit. There are a number of control strategies underground mines can take to achieve this level such as increased ventilation, installing newer engines with better exhaust profiles or use of environmental cabs. One of the most cost-effective, however, is the use of Biodiesel in high level blends such as B99.MHSA Biodiesel Findings

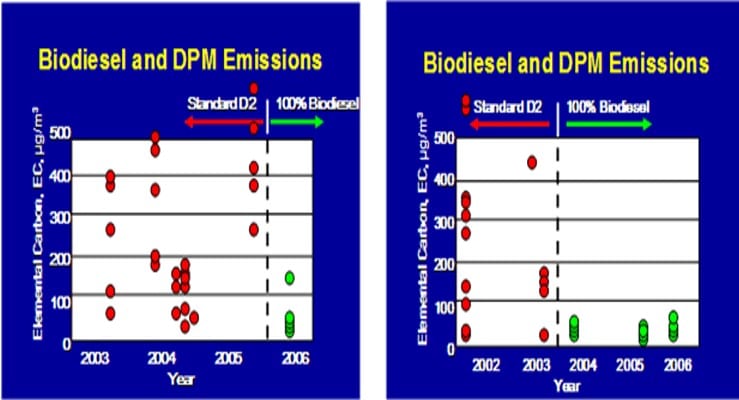

Because of the emissions characteristics of biodiesel, MSHA has been actively involved in conducting emissions sampling from underground mining equipment & machinery using standard diesel (D2) and high-level biodiesel blends (B99, B100). MHSA sampling in a number of underground metal and non-metal mines has found significant reductions in effective carbon levels occur with increased biodiesel blend levels, as can be seen in the figures below containing MHSA data from two separate underground mines.

Biodiesel in Underground Mines: Benefits Beyond Air Quality

The MHSA has endorsed biodiesel primarily as a means of reducing total and elemental carbon levels in underground mines and meeting the required exposure limits. But using Biodiesel in the underground mining sector comes with a number of other important benefits, including: State-level incentives: Some U.S. states offer incentives such as an exemption from the diesel fuel tax. Price Advantage: Biodiesel can be priced lower than traditional diesel in locations where Biodiesel terminals are present. Diesel engine maintenance: Biodiesel offers much greater lubricity than standard diesel fuel, and can act as a cleaning agent for pumps and injectors, helping lower recurring OPEX for mine operators. Low flammability: Biodiesel is safer to use in underground mines due to its higher flashpoint (266°F) compared to standard diesel.Background on the U.S Underground Mining Sector

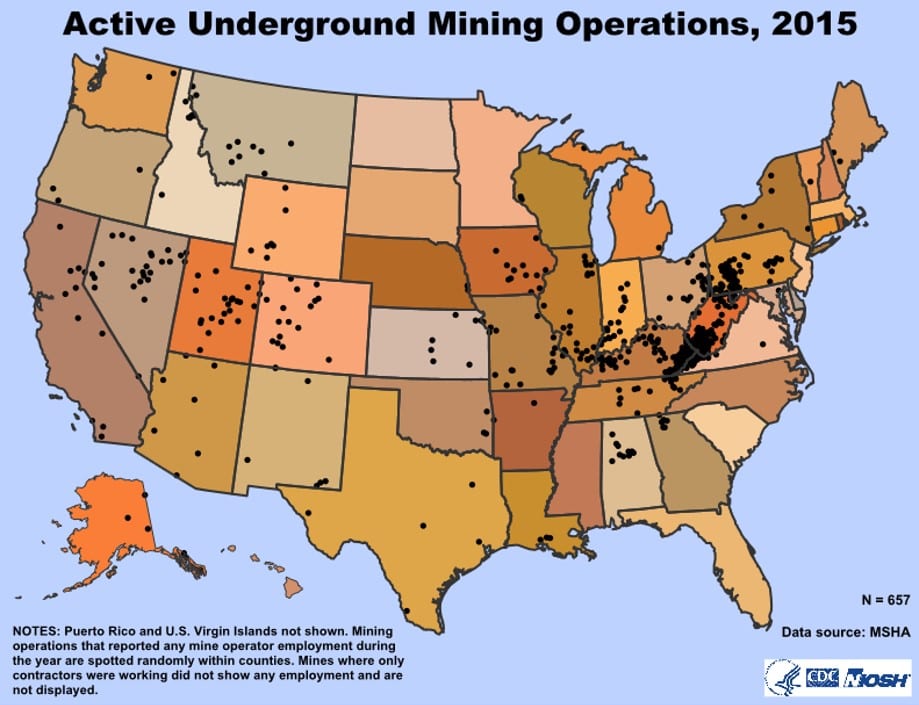

According to t

The Targray Biofuels Division is one of the largest and fastest-growing biodiesel suppliers in the United States. A certified BQ-9000 Biodiesel Marketer since 2014, The company supplies high-level blends of biodiesel to fuel retailers and distributors across several U.S states. It is committed to providing customers with innovative business solutions aimed at maximizing profits and growth, and meeting specific blending and emissions requirements while helping create a more sustainable economy for future generations.