Targray high-performance LFP Cathode Material

Developed in consultation with the industry’s premier cathode material manufacturers, Targray high-performance LFP cathode powders are engineered to help extend cycle life, rate capability and low temperature performance in lithium iron phosphate batteries. For more information about our LFP cathode product line, consult the table below or contact the Battery Division.

Lithium Iron Phosphate Batteries

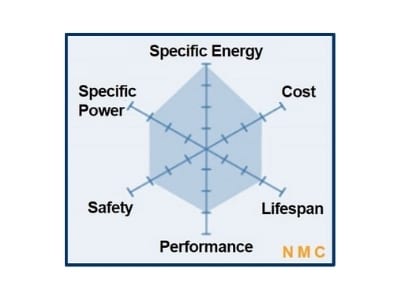

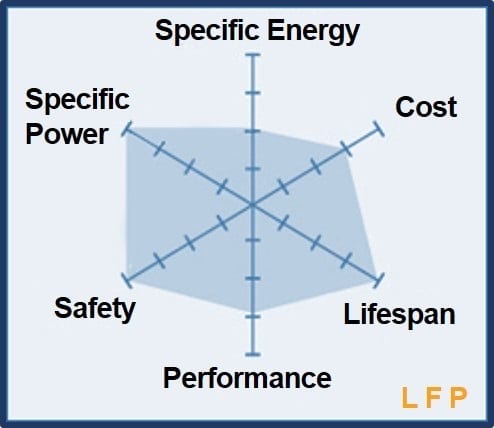

Lithium Iron phosphate (LFP) is a popular, cost-effective cathode material for lithium-ion cells that is known to deliver excellent safety and long life span, which makes it particularly well-suited for specialty battery applications requiring high load currents and endurance.

Lithium Iron phosphate (LFP) is a popular, cost-effective cathode material for lithium-ion cells that is known to deliver excellent safety and long life span, which makes it particularly well-suited for specialty battery applications requiring high load currents and endurance.

Discovered by University of Texas researchers in the mid-90s, LFP cathode offers several key advantages including a high current rating, long cycle life, and superior thermal stability, which makes it one of the safest and most abuse-tolerant cathode material options available to manufacturers. On the other hand, LFP delivers a lower nominal voltage, which results in lower specific energy when compared to other cathode materials on the market. Consequently, LFP batteries tend to have a higher self-discharge than other Li-ion battery types.

Targray LFP Cathode Features & Applications

| Product | Features and Applications |

| PLFP02113 |

Applications: High powered batteries; Batteries with low temperature requirements such as e-buses. |

| SLFP2002 |

Applications: High energy-density batteries; Batteries with significant temperature resistance requirements such as energy storage systems, power tools and electric vehicles. |

Targray LFP Cathode Product Specifications

| Items | Equipment/Method | Unit | SLFP02113 Specification |

SLFP02114 Specification |

SLFP02002 Specification |

| Surface Area | Mountech Macsorb – 1201 / BET | m²/g | 13±2 | 13±2 | 13±2 |

| Tapped Density | Quantachrome AT-2 | g/mL | 1.0±0.2 | 1.0±0.2 | 1.0±0.2 |

| Particle Size (D10) | MALVERN HYDRO 2000S | μm | <3.0 | <3.0 | <1.5 |

| Particle Size (D50) | 4.0±2.0 | 6.0±2.0 | 4.0±2.0 | ||

| Particle Size (D95) | <25 | <25 | <15 | ||

| Moisture | KEM MKC-520 ADP511S | ppm | <800 | <800 | <700 |

| Element Analysis | |||||

| Li | Perkin Elmer Optima 7200DV / ICP-OES | % | 4.2±0.5 | 4.2±0.5 | 4.2±0.5 |

| Fe | 35±1.5 | 35±1.5 | 35±1.5 | ||

| P | 20±1 | 20±1 | 20±1 | ||

| Carbon | 1.5±0.2 | N/A | N/A | ||

| Electrochemical | |||||

| 1st Charge @ C/10 | Arbin BT2000 | mAh/g | — | — | — |

| 1st Discharge @ C/10 | — | — | — | ||

| 2nd Charge @ C/10 | — | — | — | ||

| 2nd Discharge @ C/10 | 160±3 | 160±3 | N/A | ||

| Capaicty | Arbin BT2000 Discharge Capacity @ 25°C | N/A | N/A | 153±3 | |

| 1st Coulomb’s efficiency | Arbin BT2000 | % | >90 | >90 | >90 |

Working closely with our supply partners and organizations including the Electrochemical Society and NAATBatt International, we help lithium-ion battery manufacturers and researchers worldwide commercialize ambitious new technologies for the energy storage market.