Targray NMC Powder for Battery Manufacturers

Targray’s high-performance NMC battery material is engineered to meet the quality, dependability, efficiency and safety demands of next generation lithium-ion cell manufacturers. For more information about NMC cathode powder, consult the table below. To review product specifications, or to learn about purchasing our NMC battery material in commercial quantities, contact the battery division.

Lithium Nickel Manganese Cobalt Oxide Batteries

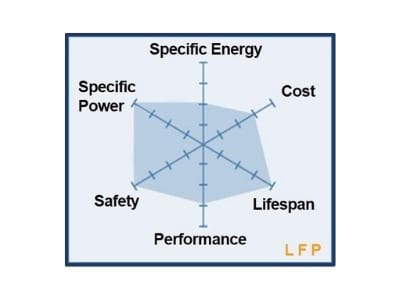

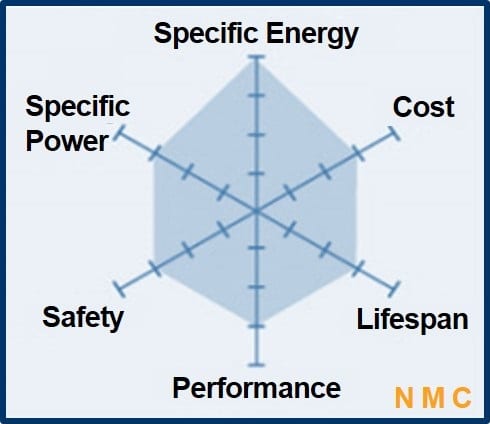

One of the most successful li-ion cathode formulas developed to date is obtained by combining nickel, manganese, and cobalt. Lithium-Nickel-Manganese-Cobalt-Oxide (LiNiMnCoO2), abbreviated as NMC, has become the go-to cathode powder to develop batteries for power tools, e-bikes and other electric powertrains. It delivers strong overall performance, excellent specific energy, and the lowest self-heating rate of all mainstream cathode powders, which makes it the preferred option for automotive batteries.

While NMC powder can refer to a variety of blends, the formula typically consists of 33% nickel, 33% manganese and 33% cobalt. This blend, sometimes referred to as 1-1-1, is a popular option for mass-produced cells in applications requiring frequent cycling (automotive, energy storage) due to the reduced material cost resulting from lower cobalt content.

NMC 333 Powder Specifications

| Product Code | SNMC

03001 |

|

| Material | NMC 333 | |

|

Physico-chemical properties |

D10/um | 4.2 |

| D50/um | 6.5 | |

| D90/um | 11 | |

| BET/m2/g | 0.48 | |

| TD/g/cm3 | 2.2 | |

| PH | 11.1 | |

| Li2CO3/% | 0.05 | |

| LiOH/% | 0.03 | |

|

Electro-chemical data 2.8-4.25V |

Capacity/ mAh.g-1 | 154.8 |

| Efficiency/% | 88.8 | |

| Rate capacity retention/% | 94.8 | |

| Cycle capacity retention @50 cycles/% | 98.3 | |

NMC 532 Powder Specifications

| Product Code | SNMC

03002 |

SNMC

03010 |

SNMC

03009 |

|

| Material | NMC 532 | |||

|

Physico-chemical properties |

D10/um | 6.2 | 5 | 3.7 |

| D50/um | 11 | 10.1 | 6.4 | |

| D90/um | 20.7 | 18.2 | 10.7 | |

| BET/m2/g | 0.24 | 0.45 | 0.51 | |

| TD/g/cm3 | 2.63 | 2.25 | 1.78 | |

| PH | 11.56 | 11.5 | 11.15 | |

| Li2CO3/% | 0.08 | 0.13 | 0.08 | |

| LiOH/% | 0.09 | 0.10 | 0.02 | |

|

Electro-chemical data 2.8-4.25V |

Capacity/ mAh.g-1 | 166.9 | 166.1 | 187.0@4.5V |

| Efficiency/% | 89.3 | 88.1 | 86.0@4.5V | |

| Rate capacity retention/% | 93.4 | 94.9 | 94.3@4.5V | |

| Cycle capacity retention @50 cycles/% | 95.6 | 99.2 | 96.1@4.5V | |

NMC 622 Powder Specifications

| Product Code | SNMC

03006 |

|

| Material | NMC 622 | |

|

Physico-chemical properties |

D10/um | 7 |

| D50/um | 10 | |

| D90/um | 19 | |

| BET/m2/g | 0.28 | |

| TD/g/cm3 | 2.5 | |

| PH | 11.65 | |

| Li2CO3/% | 0.25 | |

| LiOH/% | 0.13 | |

|

Electro-chemical data 2.8-4.25V |

Capacity/ mAh.g-1 | 175.8 |

| Efficiency/% | 90.3 | |

| Rate capacity retention/% | 93.4 | |

| Cycle capacity retention @50 cycles/% | 98.1 | |

NMC 811 Powder Specifications

| Product Code | SNMC

03008 |

|

| Material | NMC 811 | |

|

Physico-chemical properties |

D10/um | 6.7 |

| D50/um | 13.8 | |

| D90/um | 25.1 | |

| BET/m2/g | 0.49 | |

| TD/g/cm3 | 2.31 | |

| PH | 12.13 | |

| Li2CO3/% | 0.64 | |

| LiOH/% | 0.43 | |

|

Electro-chemical data 2.8-4.25V |

Capacity/ mAh.g-1 | 203.4@4.3V |

| Efficiency/% | 88.4@4.3V | |

| Rate capacity retention/% | 94.0@4.3V | |

| Cycle capacity retention @50 cycles/% | 93.4@4.3V | |

Working closely with supply partners and organizations including the Electrochemical Society and NAATBatt International, we help lithium-ion battery manufacturers and researchers worldwide commercialize ambitious new technologies for the EV battery and energy storage market. Contact us today to learn more.