PV Backsheet Material for Photovoltaic Manufacturing

The PV Backsheet material you choose for your solar panel will have a considerable impact on how it withstands the elements and performs over the course of its lifetime. A reliable backsheet should be able to provide protection from moisture, physical damage and UV rays, while also minimizing electrical discharge and thermal degradation.

Offered in partnership with one of the European solar industry’s leading backsheet technology developers, our PV backsheets are compatible with a wide range of module technologies and ideally suited to the needs of today’s solar manufacturers. They are designed to help solar module producers maximize their cell quality and reliability, while significantly lowering their manufacturing cost-per-watt.

Our Solar Backsheet Products Include:

- Fluropolymer-based backsheets for crystalline modules

- Fluoropolymer-free backsheets for crystalline modules

- Backsheets for thin-film modules

- Backsheets for flexible modules, organic PV

- Backsheets for bifacial cells

- Backsheets for floating modules, sea water applications

PVF Backsheet

| Material composition | Old IEC Partial discharge | New IEC DTI |

| Tedlar®PVF film/ PET/ Tedlar®PVF film | 1.000 V in air | 1.500 V |

| Tedlar®PVF film/ PET/primer | 1.000 V in air | 1.000 V |

| Tedlar®PVF film/ PET/primer | 1.500 V |

PVDF Backsheet

| Material composition | Old IEC Partial discharge | New IEC DTI |

| Kynar®PVDF film/PET/Kynar®PVDF film | 1.000 V in air | 1.500 V |

| Kynar®PVDF film/PET/ primer | 1.000 V in air | 1.000 V |

| Kynar®PVDF film/PET/ primer | 1.500 V |

PVDF Backsheet

| Material composition | Old IEC Partial discharge | New IEC DTI |

| UV resistant PET/PET/primer | 1.000 V in air | 1.000 V |

| UV resistant PET/PET/primer | 1.500 V | |

| UV resistant PET/primer | 1.000 V in air | 1.000 V |

|

|

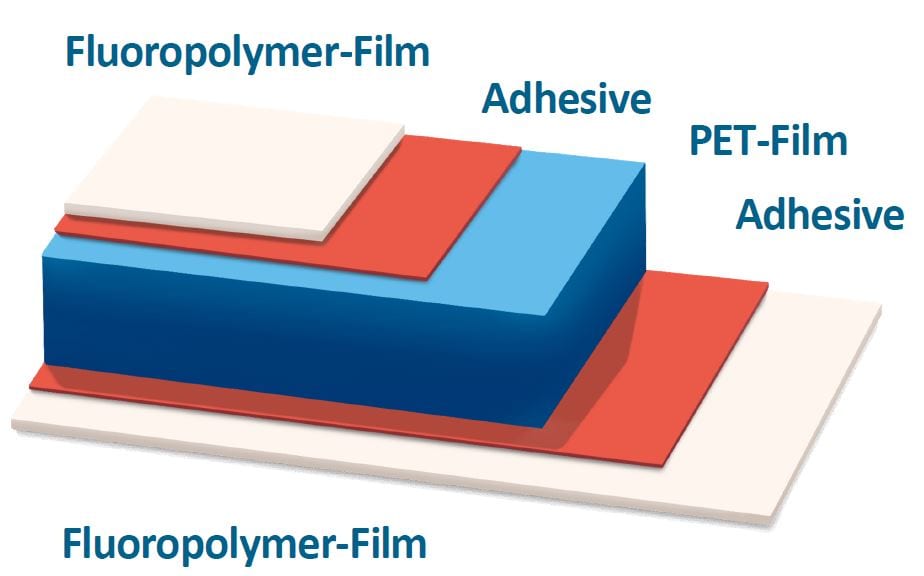

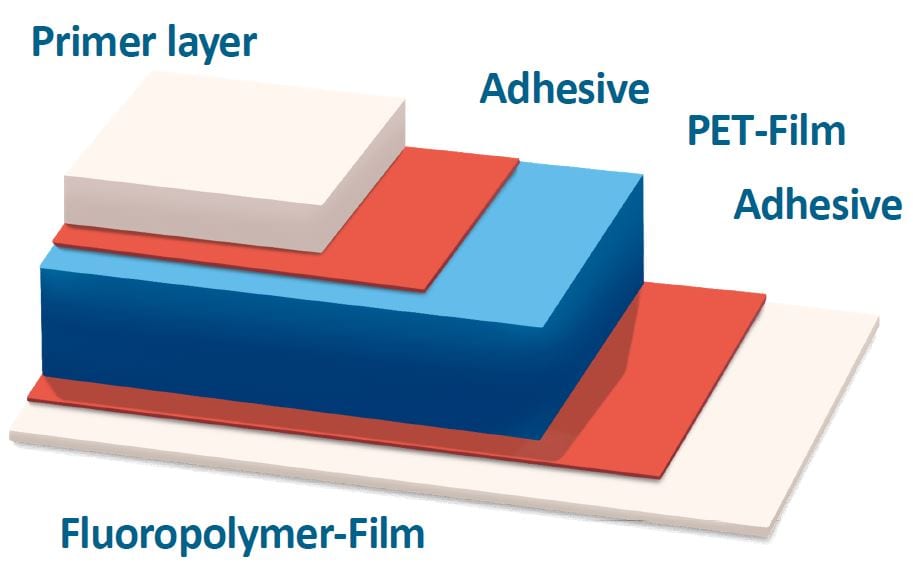

| TPT/KPK Fluoropolymer Film | TPE/KPE Fluoropolymer Film |

|

|

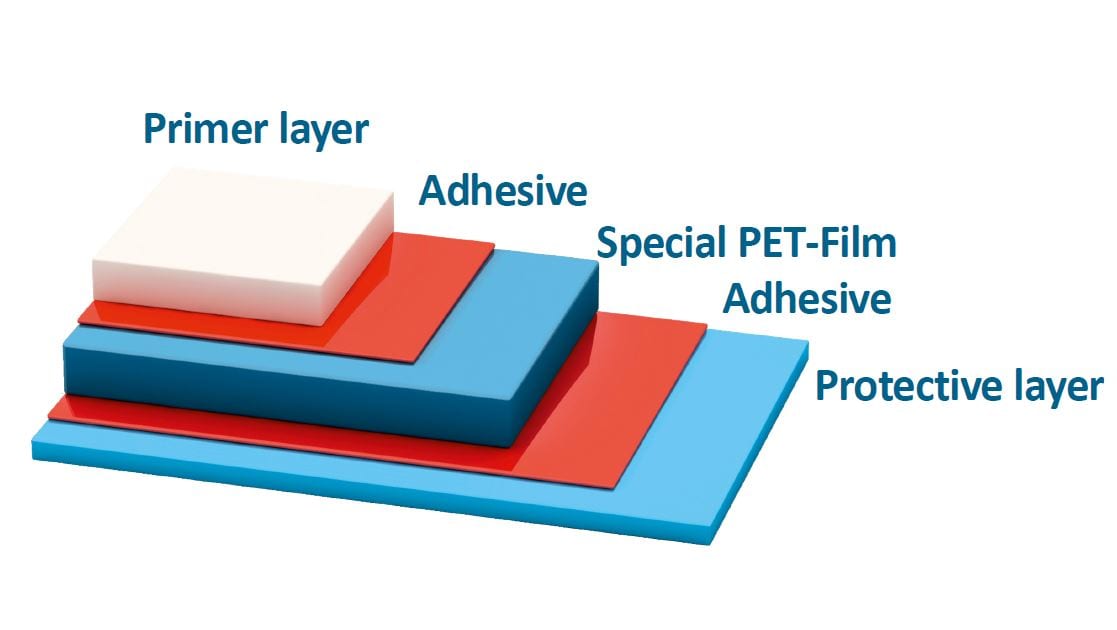

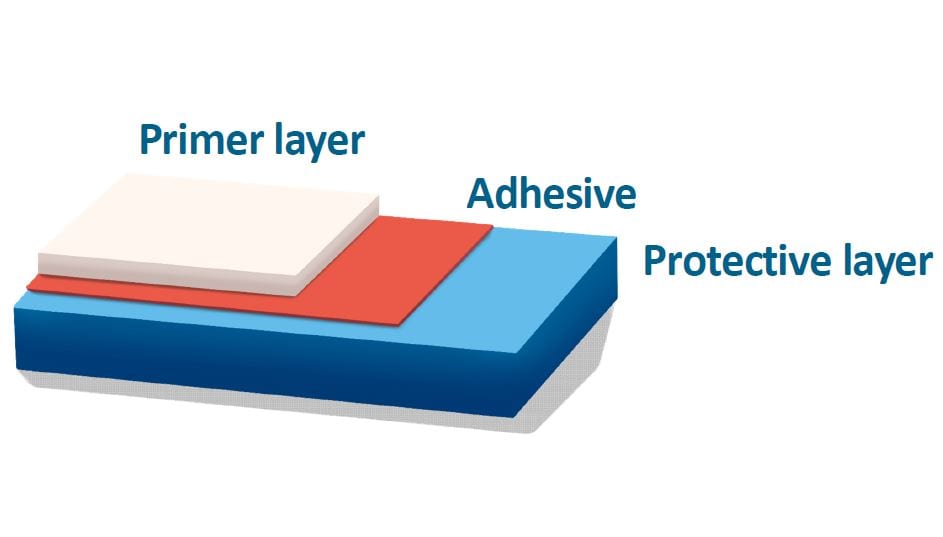

| PPE Fluoropolymer Film | PPE Layer 2 Fluoropolymer Film |

Backsheet colors offered

|

|

The Role of Backsheets in PV Manufacturing

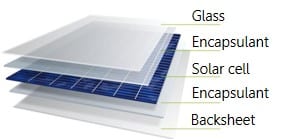

The primary function of the PV backsheet material is to offer protection to the solar module’s various components throughout its lifetime. This in turn ensures loss-free energy generation for the solar panel. The solar backsheet should be able to resist active environmental elements such as moisture, temperature changes, chemical substances and physical damages for years on end. The active electrical elements found within the modules must also be insulated to ensure the safety of surroundings. The PV backsheet material is layered atop an encapsulant on the solar cell:

Working closely with our supply partners and organizations including U.S-based SEIA, we help solar manufacturers and developers worldwide unlock value in their supply chains.