Battery Binder Solutions

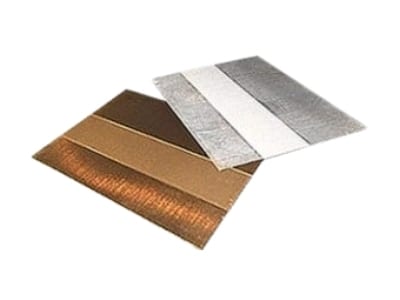

Targray supplies battery-grade binders used in the slurry making process for Lithium-ion batteries. Specialty binder powder formulations such as Hydrophilic, SBR and PVDF are used in Lithium-ion battery technology to hold the active material particles together and in contact with the current collectors i.e. the Aluminum Foil (Al foil) or the Copper Foil (Cu foil).

Given the intricate nature of the manufacturing steps outlined above, the binder powder formula’s characteristics are highly significant and must conform to strict criteria. Primary characteristics of relevance are:

|

|

Working alongside organizations including Electrochemical Society and NAATBatt, we’re focused on helping battery manufacturers commercialize ambitious new energy storage technologies.