LTO Anode Materials for Battery Manufacturers

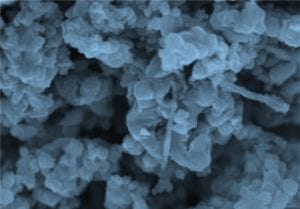

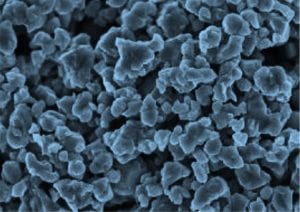

Targray’s LTO battery anode portfolio include various formulas of high-performance lithium titanate powder optimized for use in lithium-ion battery manufacturing. Our LTO anode materials can be customized to meet the specific requirements of battery and energy storage researchers, developers and manufacturers.

Typical uses for lithium titanate include electric powertrains, UPS and solar-powered street lighting. More recently, LTO battery anodes have been evaluated for use in EVs, HEVs, Energy Storage Systems (ESS), and supercapacitor applications. For a complete review of our LTO product specifications, please contact us.

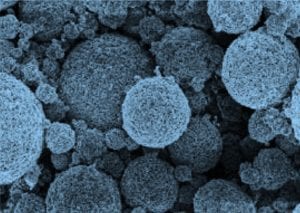

Lithium Titanate Powder for LiB Applications

Lithium titanate (LTO) replaces the graphite in the anode of a standard lithium-ion battery and the material forms into a spinel structure. It can be used in combination with LMO or NMC cathode. LTO carries certain advantages over the conventional Li-ion with graphite anode, including the absence of SEI film formation and lithium plating when fast charging and charging at low temperature.

LTO’s Thermal stability under high temperature is superior to other Li-ion systems. Moreover, LTO powder prevents the occurrence of aluminum alloying, which in turn enables the aluminum current collector to generate a significantly enhanced gravimetric capacity compared to copper.

| Appearance |  |

| Efficiency % | ≥93.0 |

| Appearance |  |

| Efficiency % | ≥92.0 |

| Appearance |  |

| Efficiency % | ≥92.0 |

Working alongside organizations including Electrochemical Society and NAATBatt, we’re focused on helping battery manufacturers commercialize ambitious new energy storage technologies.