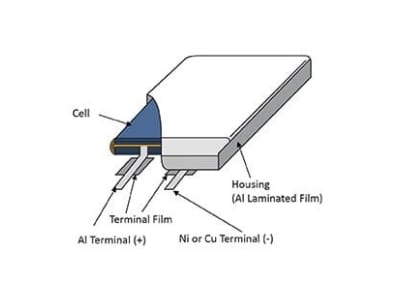

Laminated Battery Tapes for Pouch Cell Manufacturing

Engineered to provide class-leading formability, insulation, seal strength, and corrosion & water vapor resistance, Targray’s battery tape material delivers the performance required by today’s lithium-ion pouch cell manufacturers. Developed using acid-modified polypropylene and polyester materials, our laminated tape solutions can help battery manufacturing companies produce more stable li-ion pouch cells with a longer shelf-life.

To learn more about the performance of our laminated tape materials for lithium-ion pouch cells, consult the summary below. For complete specifications and information about pricing and availability, please contact the Battery Division.

Product Specifications

| Unit | Direction | Reference Value | |

| Tensile Strength | MPa | MD | 44 |

| TD | 22 | ||

| Tensile Stretch Rates | % | MD | 3.2 |

| TD | 8.9 |

Characteristics of Laminated Tape Material

| Unit | Material | Reference Value | |

| Melting Point | Celsius | Acid-modified polypropylene | 147 |

| Polyester | 310 – 340 | ||

| Density | MD | Acid-modified polypropylene | 0.90 |

| TD | Polyester | 1.40 |

Working closely with our supply partners and organizations including the Electrochemical Society and NAATBatt International, we help lithium-ion battery manufacturers worldwide commercialize ambitious new technologies for the energy storage market.

Related Battery Materials

Battery Tab Materials

Our battery tab includes aluminum (Al) tabs for positive electrodes, and copper (Cu) tabs for negative electrodes.