Battery Tab Materials for Lithium-ion Cell Manufacturers

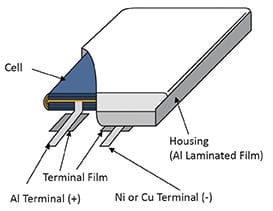

Battery tabs play an important role in lithium-ion cell manufacturing. Typical large format lithium-ion cells use copper for the anode foil (current collector) and aluminum for the cathode foil. A ‘foil-to-tab’ weld is needed to gather all the current collector plates (foils) inside the cell and join them to a tab. The tab then exits the cell casing, which allows the cell’s energy to be transferred to an external source.

There are two foil-to-tab welds in each li-ion cell, and hundreds of cells in a standard lithium-ion battery pack.

Targray Battery Tabs Portfolio Summary

Our battery tab portfolio is built to meet the modern requirements for lithium-ion battery and energy storage manufacturing. It includes aluminum (Al) tabs for positive electrodes, and copper (Cu) tabs for negative electrodes. In addition, we can supply copper-plated Aluminum (Cu-Al), nickel (Ni), and aluminum-clad copper tabs. Our tabs are available with or without polypropolene film, and black or yellow DNP.

- Material and cladding options: Many varieties of nickel, copper, aluminum-based tabs

- Thickness: 0,010 – 0,150 mm

- Tolerance: +/- 10% on nominal thickness

- Width: 1,0 – 10 mm

- Packaging: Wound on spools or plastic core with side shields

- Customization: Custom dimensions for thickness and width can be produced on request

Battery-grade Nickel Strips

- Rolled Nickel foil, slit to narrow strips or wider sheets

- Thickness options ranging from 0,010mm to 0,150mm

- Exceptional corrosion-resistance

- Suitable for standard tabs and connection plates (stacks)

Aluminum-clad Copper Strips (Al-Cu)

- Excellent welding connection with anode (Cu) and cathode (Al) materials

- Combines the corrosion resistance of aluminum with the high conductivity of copper

- Suitable for high-conductive battery tab ribbons

- Silver- or tin-clad strips for soldering connections also available

Battery-grade Copper Bus Bars

- Built using special copper grade C103 for laminated bus bars

- Outstanding durability and flexibility, confirmed by long-term cycle testings

- Standard thickness of 35µm, with many more sizing options available on request

- Ideally suited for battery electrification and automotive connectors (EV)

Working alongside organizations including Electrochemical Society and NAATBatt, we’re focused on helping battery manufacturers commercialize ambitious new energy storage technologies.