Graphene Materials for Rechargeable Batteries

Graphene anode materials have the potential to play an important role in lithium-ion battery manufacturing industry. Battery graphene can enhance conventional electrode performance, leading to batteries that are lighter, more durable, lower-cost, faster-charging and better suited for high-capacity energy storage.

Introducing graphene anodes into battery electrodes enables researchers and manufacturers to capitalize on the material’s exceptionally high conductivity. Higher conductivity can result in faster charge/discharge rates, higher power, improved charge transfer kinetics, and longer-lasting cycle life.

Enhanced Electrode Slurry Formulations

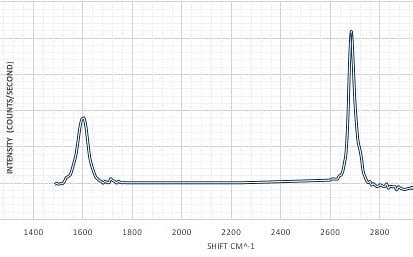

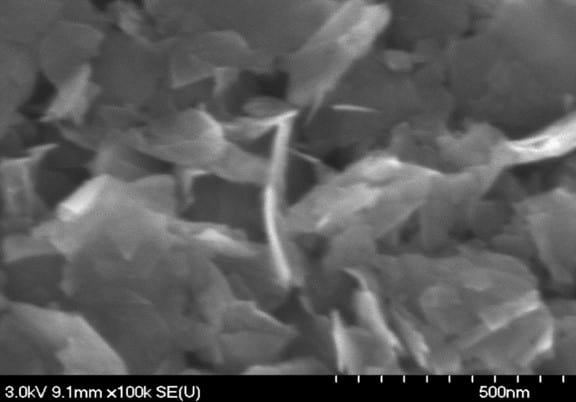

Our high-performance powdered graphene materials are produced using an innovative process that eliminates the use of acids and oxides. The process is economical and easily scaled to industrial sized applications. Our graphene can be produced from ultra-pure graphite (>99.995%) eliminating any concerns over potential contaminants.

Unlike other popular conductivity promoters, graphene powders add conductivity without significantly reducing the active component in the electrode.

Graphene Powder Performance Characteristics

A summary of the composition and performance characteristics of our enhanced graphene materials is provided below. For a complete review of our the solutions we provide as a global graphene supplier, speak with a Battery Division representative.

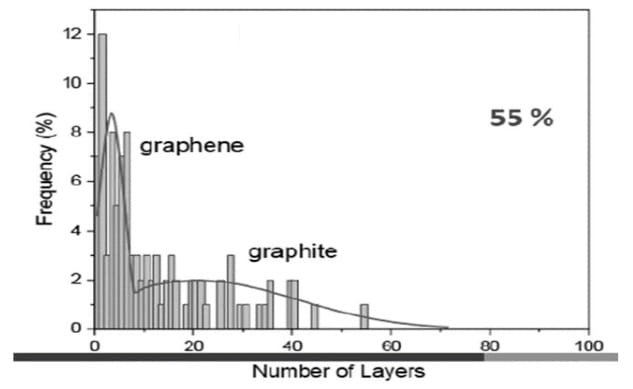

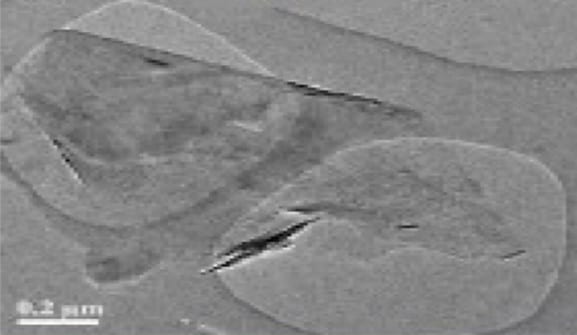

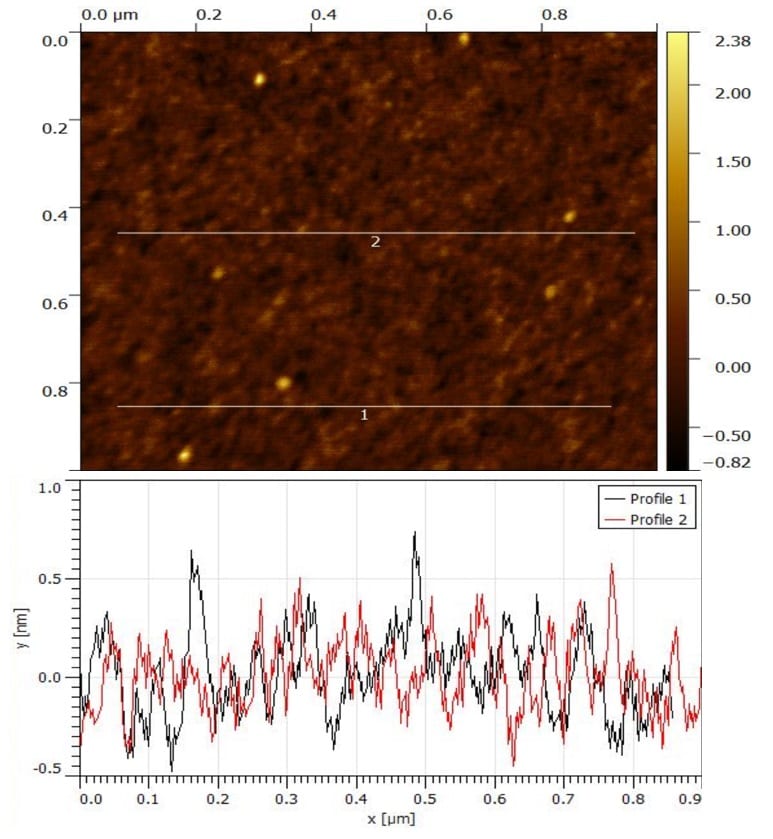

- Average Number of Graphene Layers: 1 – 5

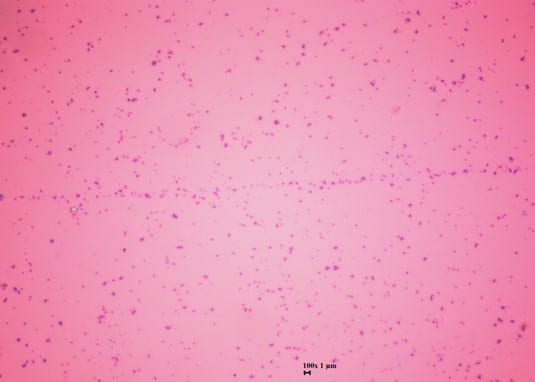

- Particle Size: 0.06μm – 5μm

- > 93% Carbon composition

- 55% Graphene by area

- Offered in suspension or powder form

- Available in commercial quantities

Related Battery Materials

Graphite Anode Materials

Conductive Carbon Materials

LTO Anode Materials

Silicon Anode Materials

Cathode Materials

Copper Foil

Electrolyte Solutions

Pouch Cell Material

Contact the Battery Division

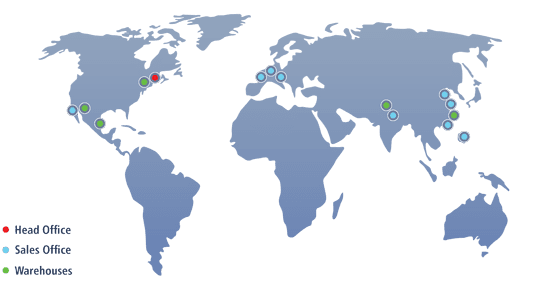

As part of the global Targray Group with employees across North America, Europe, and Asia, the Tagray Battery Division benefits from a unique network of expertise.

Drawing on a robust network of institutional partners that includes Argonne National Laband the Electrochemical Society, we are committed to delivering innovative li-ion battery materials, chemicals, and equipment solutions to meet the commercial needs of clients. Our intimate understanding of the energy storage industry supply chain enables us to create value for our customers and partners around the world. For more information, please contact us at 1-888-695-8095 or click below.