Electrodeposited Nickel Foil for Li-ion Cells

Targray markets a line of annealed, electrodeposited nickel foil materials engineered to meet the requirements of lithium-ion battery manufacturers. Offered in thicknesses ranging from 0.006-0.400mm, our ED Nickel foil is used in a variety of rechargeable battery applications including cellphones, laptops and retail electronics, as well as higher-level applications such as supercapacitors.

Targray markets a line of annealed, electrodeposited nickel foil materials engineered to meet the requirements of lithium-ion battery manufacturers. Offered in thicknesses ranging from 0.006-0.400mm, our ED Nickel foil is used in a variety of rechargeable battery applications including cellphones, laptops and retail electronics, as well as higher-level applications such as supercapacitors.

Ultra Smooth RA Nickel Foils

Advanced coating processes require extremely smooth foil surfaces for optimal deposition results. Our ultra smooth nickel foil features a surface roughness below 50nm Ra on both sides. Created to deliver superior CVD (chemical vapor deposition) coating adhesion, the foil is also suitable for single- and multi-layer graphene growth. It is available in customized rolls and sheets as a substrate material.

Product Features

- Ni foils made from high-purity nickel with optional coating for both sides.

- Dimensions | Thickness: 006mm – 0.400mm, Width: 0.6mm – 650mm

- Rolling | Wide, ultra-thin, and compatible with various materials.

- Slitting | Narrow, thin and precise slitting.

- Surface upgrades | Degreasing, roll cladding (both sides), ultra smooth

- Formats | Coils (various core sizes), sheets, etched / stamped parts

- Offered in small lots (R&D) and large lots (mass production). Extended services available.

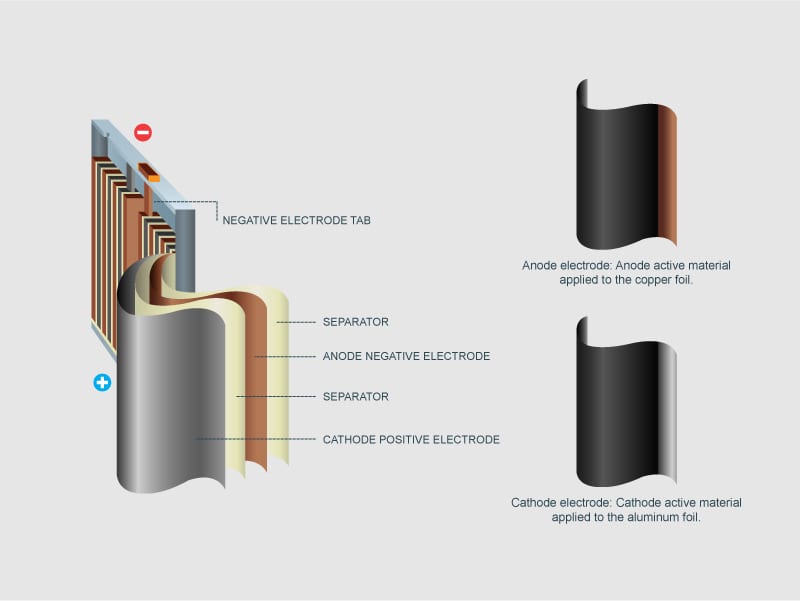

Accounting for over 90% of the electric conductivity and ∼90% of the mechanical strength of the electrode in lithium-ion batteries and capacitors, current collectors such as aluminum foil play an important role in determining the overall performance and cost-efficiency of a lithium-ion cell.

Working with supply partners and organizations including the Electrochemical Society and NAATBatt International, Targray is committed to helping manufacturers and researchers worldwide commercialize ambitious new energy storage technologies.