Targray Cathode Materials for Li-ion Battery Manufacturers

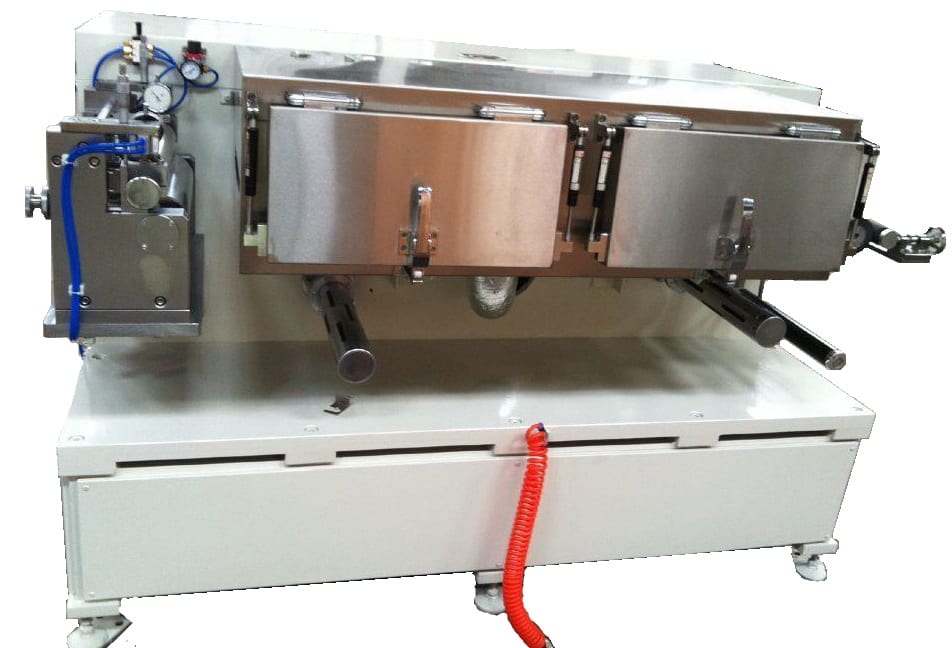

Targray’s Roll-to-Roll coater is a compact and user-friendly coating machine used to apply slurry mix onto current collectors in li-ion battery manufacturing. Scraping thickness and operating rate can be adjusted via the coater’s integrated computer panel. All components which come into contact with the slurry mix are composed of stainless steel.

Operating at a rate of up to 1 meter per minute, this R&D-scale coater solution also comes with its own drying compartment. This enables battery laboratory technicians to accelerate their production while making efficient use of dry room space.

Roll-to-Roll Coater Specifications

| Appearance |  |

| Max Width | 300mm |

| Roller Diameter | Φ100mm |

| Max. Coating Roll Diameter | Φ250mm |

| Coating Accuracy | ≤0.003mm |

| Coating Speed | 1m/min, adjustable |

| Control Pressure | 5-50N, adjustable |

| Dry Temperature | RT-150°C, adjustable |

| Oven Length | 1.2m |

| Air Compression | 0.5-0.7MPa |

| Coating Mode | Single Face Continuous Coating |

| Net Weight | ~1050kg |

| Dimensions (LxWxH) | 1800x810x1300mm |

| Power Supply | AC 110V or 220V 50/60 Hz, single phase |

| Power | 6500W |

Related Battery Materials

Cylindrical Cell Manufacturing

Cylindrical Cell Manufacturing can be broken down into 4 stages: Electrode preparation, Cell assembly, Case formation & sealing, and battery testing.

Pouch Cell Manufacturing

Lithium-ion Pouch Cell Manufacturing can be broken down into 4 stages: Electrode preparation, Cell assembly, Case formation & sealing, and battery testing.

Coin Cell Manufacturing

Lithium-ion coin cell manufacturing process using li-ion battery R&D equipment. Fabrication involves 3 simple steps.

Electrolyte Solutions

High performance battery electrolyte solutions. Produced with LiPF6 salt and a high phosphorous content flame retardant, DMMP.

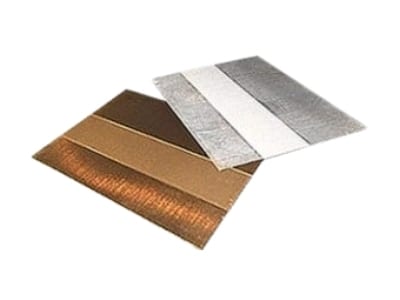

Copper Foil

An anode foil portfolio of copper current collectors including Electrodeposited (ED), rolled annealed (RA) and roll-clad Cu foils.

Nickel Foil

Annealed, ED nickel foil materials. Engineered to meet the performance demands of lithium ion battery manufacturers.

Graphite Anode Materials

Battery grade graphite powders for li ion cells manufacturers. Products include natural, artificial and composite graphite.

Battery Packaging

A large selection of battery packaging materials. Products include battery tabs, aluminum laminate film, and prismatic cans, cases & lids.